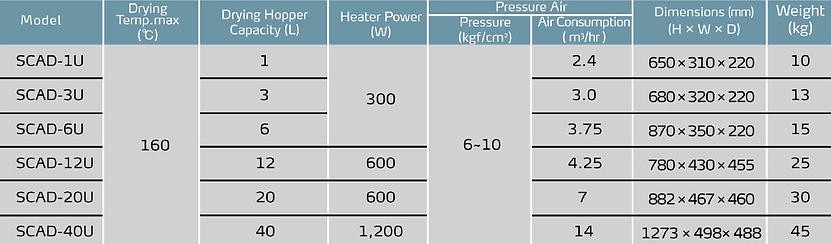

Compressed Air Dryers

SCAD Series

SCAD compressed air dryers integrate plastic drying and conveying into one unit. This is especially applicable to vertical injection moulding machines and stand injection moulding machines with workshop height limitations. The SCAD adopts positive compressed air to load materials which provides a low noise level and low energy consumption. The hot and dry air is formed by sending outfitted compressed air into pipe heaters. The unique up-blowing air pipe design enables hot air to evenly spread out to achieve the optimum drying effect.

- Low noise and energy efficient operation

- Adjustable material level sensor

- Overheat protection switch

- Compressed air design for better stability on ambient temperatures and humidity’s

- Integrated material loading through compressed air

- Industry-Leading Technology – Precision-engineered solutions that optimise performance

- Customised Systems – Tailored to meet your unique processing needs

- Expert Support – Dedicated specialists providing technical advice and aftersales service.

- Proven Reliability – Trusted by manufacturers worldwide.