Data Sheet

Innovation Meets

Reliability

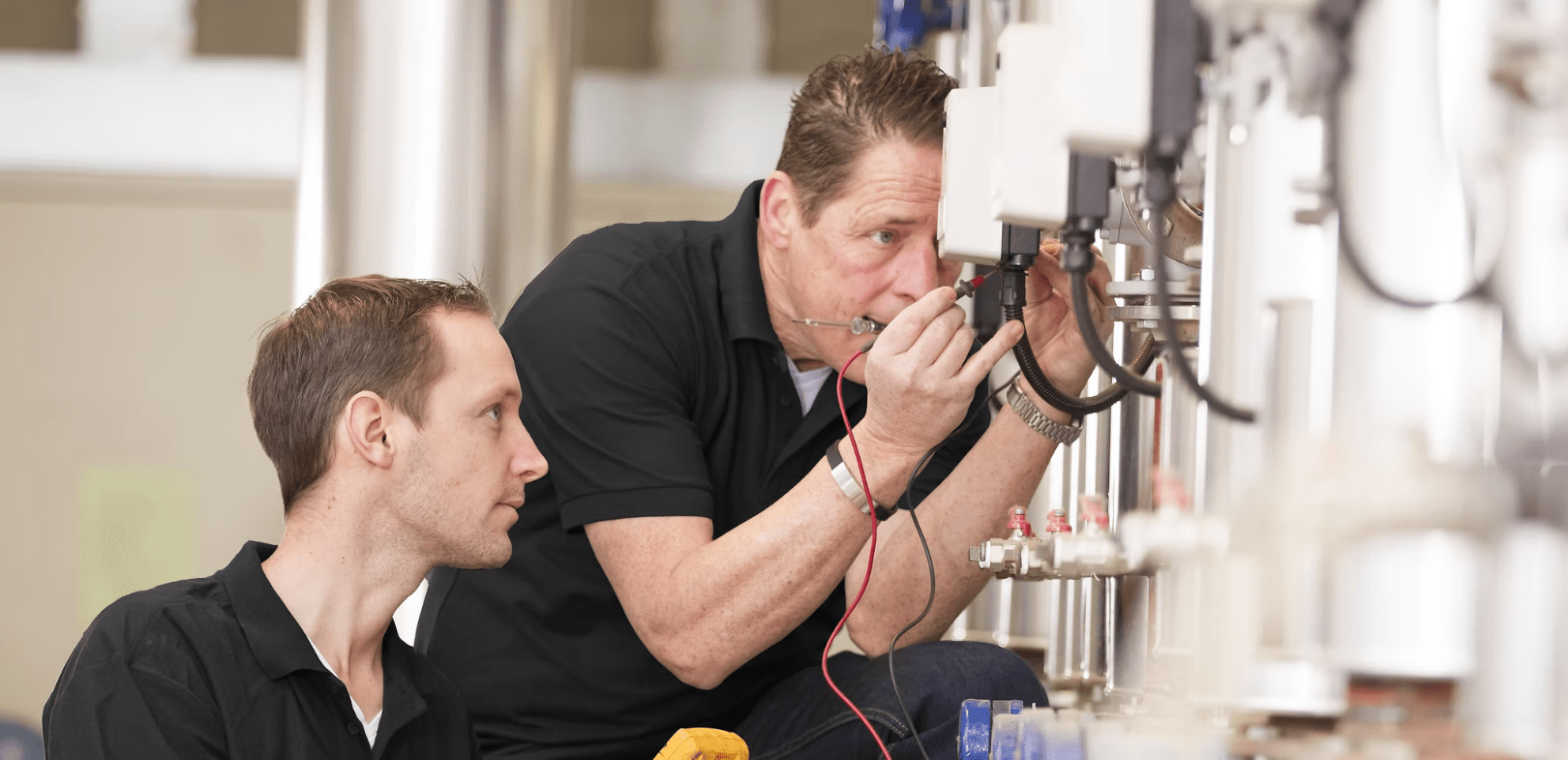

For over 40 years, Shini has been at the forefront of plastics auxiliary equipment. We combine advanced technology with British expertise to help manufacturers streamline production, reduce costs, and enhance quality.

Take Your Production Further

Power your operations with Shini’s next-generation auxiliary equipment. Speak to our experts today.

Contact us now to discuss your requirements.

Proven

Worldwide

Innovation

Meets Reliability

Over 50 years

Innovation

Meets Reliability

Over 50 years

Shini UK

Find the perfect solution for

every requirement

Contact our expert team

Trace PT Limited

(trading as Shini UK)

Unit 404 Milton Keynes Business Centre

Foxhunter Drive, Linford Wood,

Milton Keynes, MK14 6GD

United Kingdom

Telephone: 01908 533860