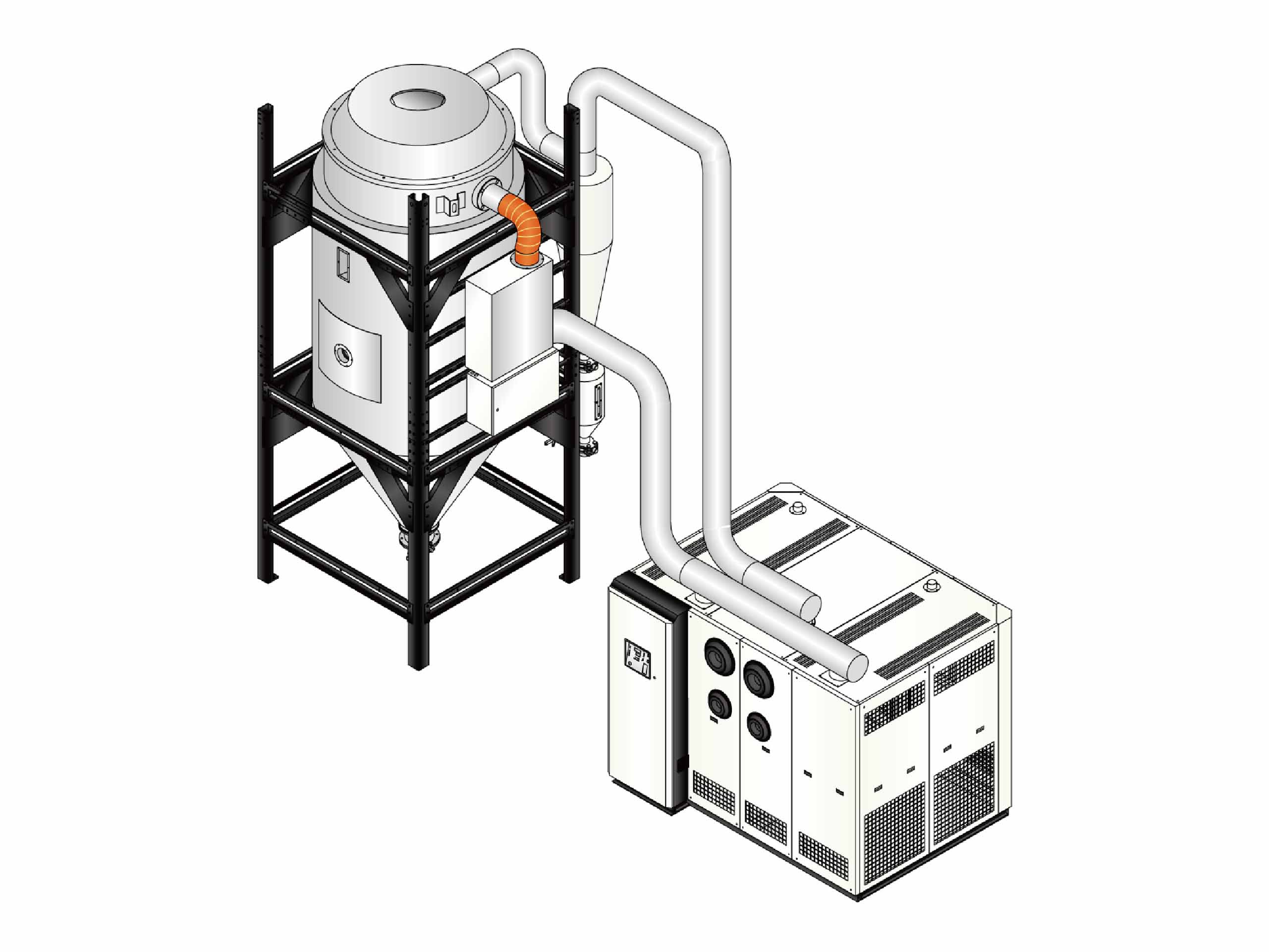

Modular Drying & Dehumidifying System

SMD Series

The Modular Drying & Dehumidifying System provides a fully flexible platform for stable, energy-efficient drying of engineering plastics.

Processors can combine drying hoppers, hot-air dryers, honeycomb dehumidifiers, and smart airflow modules to create a tailored drying setup—from a single drying station to a full centralized system supporting multiple machines.

Key Advantages

-

Fully Modular, Build-As-You-Grow Design

All components—drying hoppers, hot-air dryers, dehumidifiers, and modular control units—can be mixed and matched.

Scale from a compact workstation to a complete factory-wide drying network as production demands increase. -

High-Efficiency Honeycomb Dehumidification

SD-H series dehumidifiers use a rotating honeycomb wheel to supply low-dew-point, stable drying air for moisture-sensitive resins.

Ensures consistent moisture removal and prevents defects such as brittleness, splay, or poor mechanical strength. -

Insulated, High-Capacity Drying Hoppers

DH-U hoppers feature thick thermal insulation to reduce heat loss, improve drying efficiency, and maintain accurate temperature control—especially important for engineering materials. -

Smart Airflow Management (MHD-U / MHD-U-M)

Automated airflow adjustment via inverter control optimises air volume, reduces energy use, and keeps drying conditions stable.

Modular design allows simple expansion or reconfiguration as needed. -

Easy Capacity Expansion & System Mobility

Add hoppers to increase volume, or add dehumidifiers to boost drying performance.

Detachable floor stands and modular hardware make system relocation and reconfiguration quick and convenient. -

Wide Range of Sizes & Configurations

• Hoppers available from 20 L to 2,000 L

• Hot-air dryers from 30–4,000 m³/h

• Multiple dehumidifier capacities

Suitable for small machines, high-throughput moulding lines, or large centralized drying rooms.