7

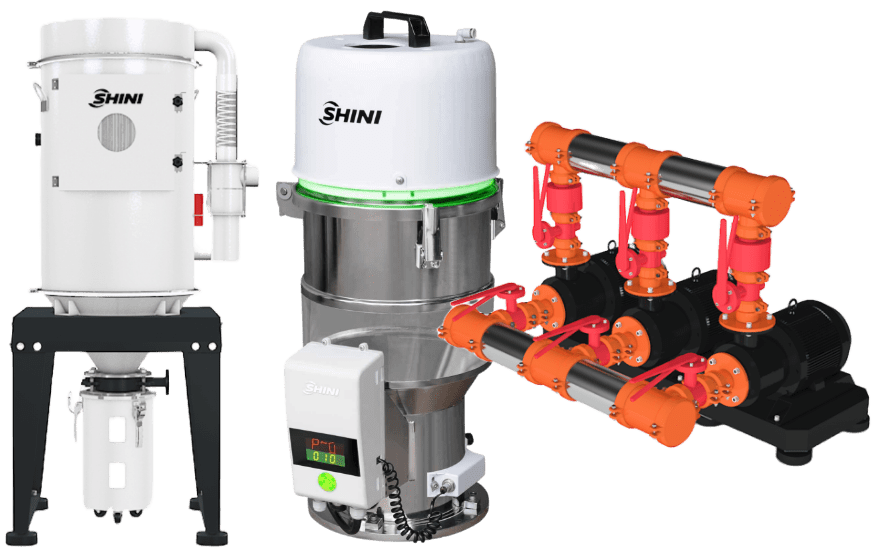

Perfectly Condition Your Material

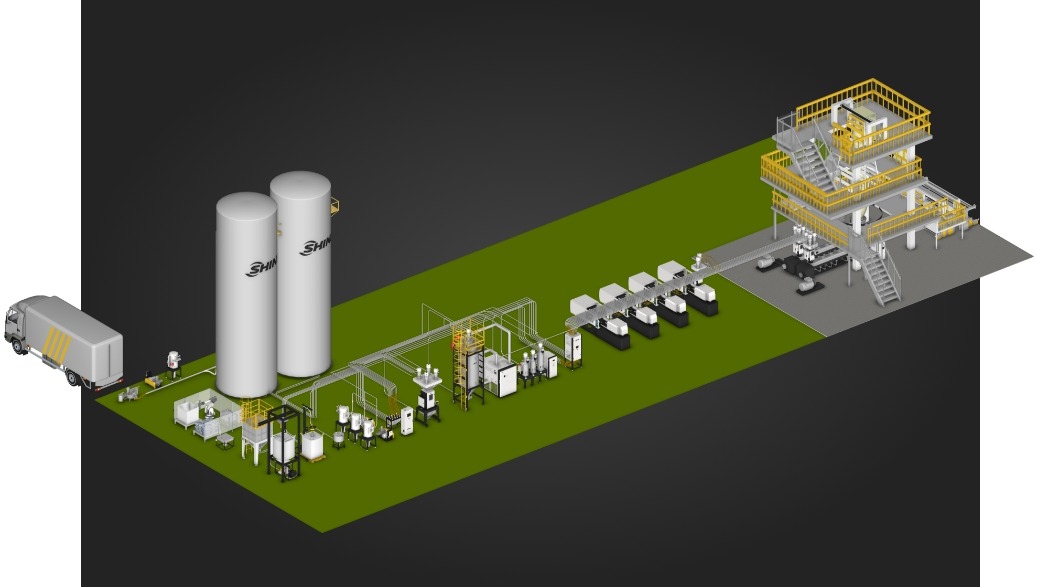

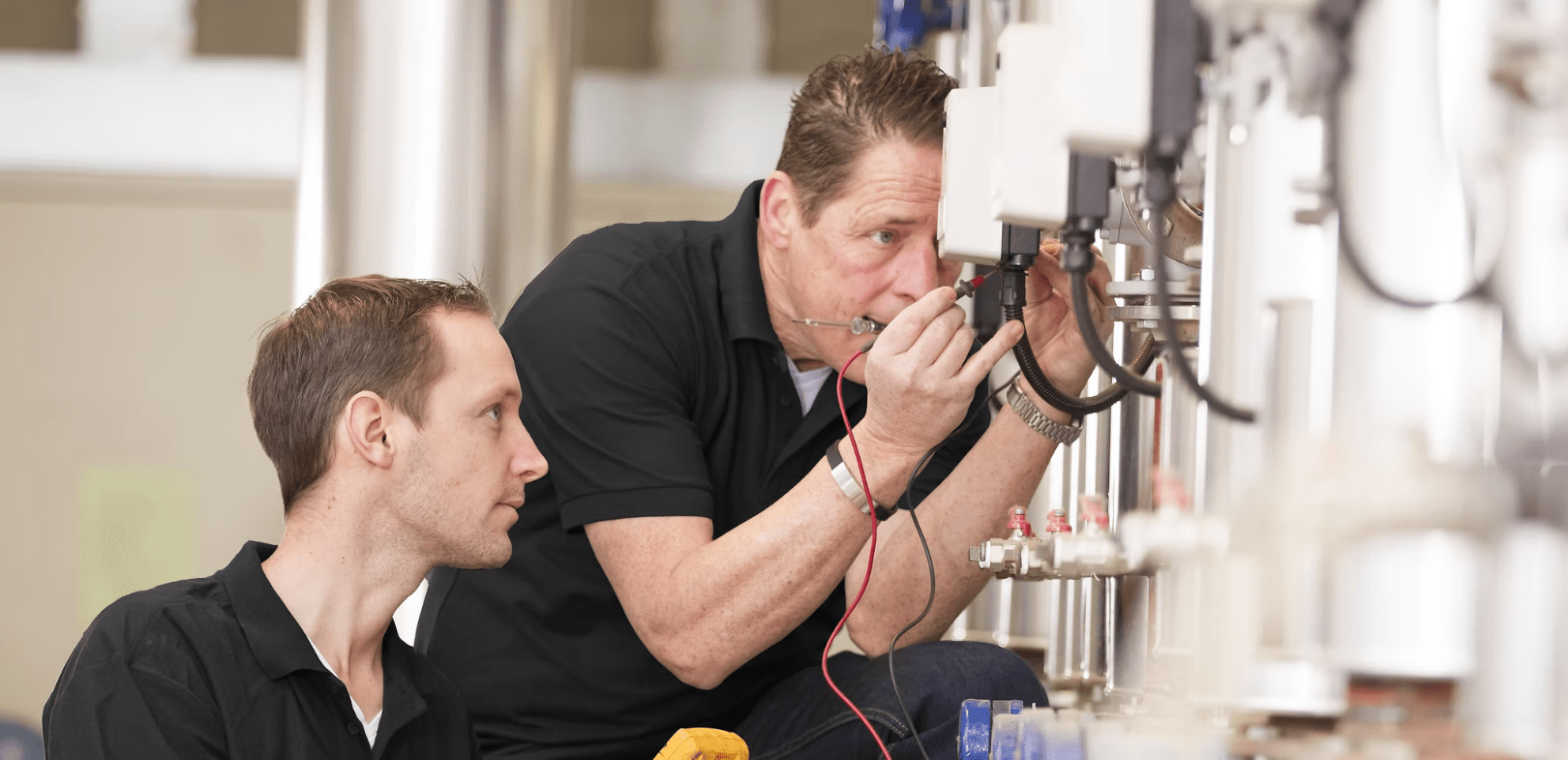

At Shini UK, we offer advanced Central Material Handling Systems designed to boost production efficiency, reduce downtime, and ensure precise material control across your manufacturing process. Whether you’re operating in plastics, packaging, or industrial automation, our systems provide a scalable and fully integrated solution tailored to your needs.

Innovation Meets

Reliability

For over 50 years, Shini has been at the forefront of plastics auxiliary equipment. We combine advanced technology with British expertise to help manufacturers streamline production, reduce costs, and enhance quality.

Why Choose Shini UK?